Proper lubrication is essential for the bearing, and we use the highest quality oils available. Our standard lubricant has an effective operating range from +10 °F to +175 °F. Applications requiring extended or unusual operating ranges must be identified so that we can select a special lubricant to do the job. This impregnation process is available for a minimal charge.

Proper lubrication is essential for the bearing, and we use the highest quality oils available. Our standard lubricant has an effective operating range from +10 °F to +175 °F. Applications requiring extended or unusual operating ranges must be identified so that we can select a special lubricant to do the job. This impregnation process is available for a minimal charge.

Supplemental Lubrication

Additional lubrication can be provided thru the use of oil soaked felts, wicks, etc., or by periodic oiling. A unique advantage of the bearing is that it does not require any grooving or holes to distribute the oil across the bearing surfaces. The bearing distributes oil evenly across the bearing face due to the microscopic pores in the material.

Storage of Bearings

Bearings must be stored in non-absorbing containers. Do not store in paper or cloth containers. Do not store in cardboard boxes! The best containers are made of plastic or metal.

De-Oiling

To remove oil from a bearing, immerse it in a solvent for 12 hours. An Aromatic solvent is recommended. Chlorinated solvents should be avoided, as they can initiate corrosion within the pores of the material. After soaking in solvent, the bearings should air dry until the absorbed solvent is evaporated.

Re-Oiling

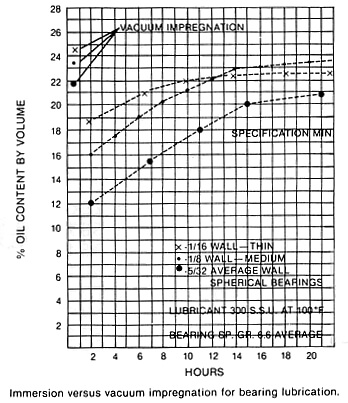

The most efficient method of impregnation is by the vacuum process. However, this process is typically available only to bearing manufacturers. Re-oiling can also be accomplished by immersing the bearings in oil heated to 150-175 °F. This method will result in a 90 saturation of the bearing material. The graph above indicates the length of time required to achieve maximum impregnation by both methods.

CUSTOM MADE BEARINGS

Custom bearings can be designed and manufactured according to customer specifications, including requirements for special dimensions and/or materials. Our inventory provides for a large supply of nearly all the powdered metal mixes used in bearing manufacture. Please give us a call and tell us about your special needs.